“It concerns four fractions of the fava bean,” explains Gijs. “Protein isolate, soluble protein isolate, an internal fibre (cell membrane) and starch. Together suitable for a wide range of food applications, from meat and dairy alternatives to sports nutrition and baking products. Thanks to the unique processing technology, each of these ingredients has a neutral odour, colour and taste. This is crucial for winning over consumers, and currently perhaps the biggest challenge in ensuring plant-based products are appealing, and remain so. They’re also attractive from a cost point of view, because not only can we process the fava bean on a large scale, but we also valorise pretty well the entire bean.”

In the media: Protein Magazine

Fava Beans: "Protein crop of the future?"

BY Meelunie 06/03/2024

How we contribute to the protein transition

How Meelunie is contributing to the protein transition by applying an innovative process to its unique ingredients.

“Meelunie is one of the largest suppliers of proteins and starches worldwide”, says Chief Innovation Officer (CIO), Gijs van Elst. “For 157 years now, we’ve been supplying ingredients for food and animal feed around the world. With our experience and expertise, we believe we can help accelerate the protein transition. Developing plant-based ingredients from fava beans is a big step towards that.”

(Eiwitmagazine, Partner article, March 2024)

Fifteen years’ research

As Gijs explains, the fava bean, or field bean, has a very high protein content, and is comparable to the broad bean. “Fava beans have for years been used as a component in the processing of animal feed. We’ve now made them widely available for human food products.”

The development of the groundbreaking processing technology, results in a unique combination of existing plant extraction techniques combined with innovations borrowed from the dairy industry*. “We’ve developed a process methodology that extracts different ingredients from the fava bean, and gives it a neutral colour and taste, without losing the unique nutritional and functional properties of the various parts of the bean. The ingredients are rich in fiber and protein, and free of cholesterol or saturated fats. What’s more, fava beans are not classified as an allergen.”

Locally grown

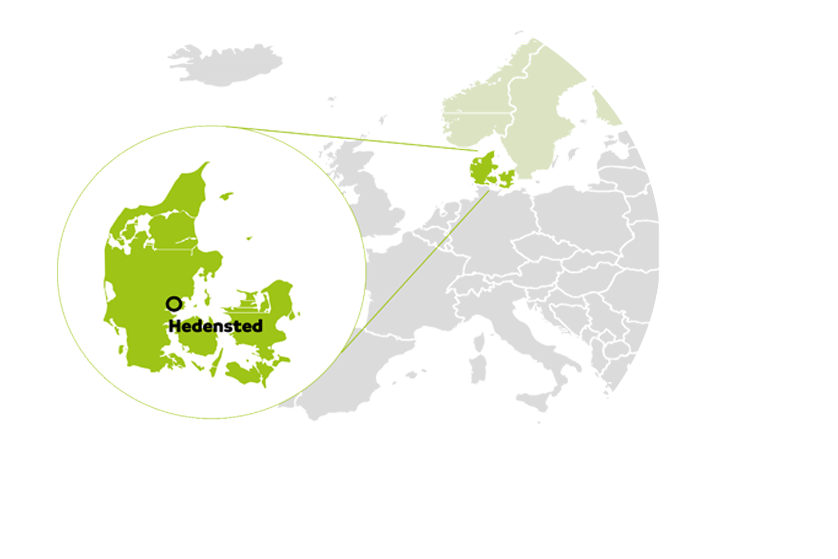

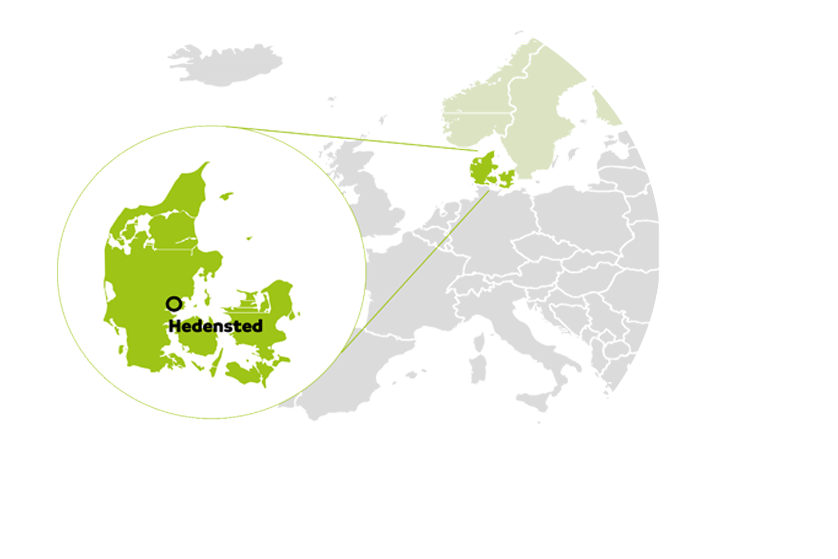

Cultivation takes place in Denmark, where a sustainable factory for processing the beans is also located. “Fava beans thrive in a cool climate,” explains Gijs, “which of course is a big plus point in terms of sustainability, as you don’t have to source them from far away.” Gijs believes in this respect, the fava bean is an excellent alternative in Europe to soya. “Its limited availability and suitability has been a handbrake on the protein transition, and the introduction of these ingredients from European soil will speed up the process. But it’s certainly not our ambition to compete with soya.”

Unique Soluble Isolate Protein

The CIO sees the soluble fava protein isolate in particular as unique. “Most proteins don’t dissolve in water. This product’s strong emulsifying properties also make it a good substitute for egg protein in plant-based mayonnaise, for example. You can also make a stable foam from it, which can be useful in making, say, plant-based dairy (barista) variants. The internal dietary fibre is a good binder of fat and water, and has a sort of ‘sponge effect’ that creates the juicy texture and appropriate mouthfeel for meat substitutes. While the starch ingredient in the fava bean is suitable for use in the noodle and pasta industry, for example, and could prove an interesting plant-based alternative to gelatine.”

Sustainable factory

The factory in Hedensted, Denmark, where the high-quality ingredients are produced, has been designed with a focus on sustainability. “Sustainability is fully integrated into the business model. For example, the water used in the production process is filtered and reused to create a circular system. And we are in discussions with the municipality of Hedensted about using the collected residual heat to connect to the local heating system. In addition, the entire bean is valorised during the process, so no residual product remains. At the moment, only the husk is used for bio-fermentation.”

More information about our factory can found on the meeluniegpi website.

Nitrogen-fixing

Gijs also points to the significant sustainability benefits of the agricultural technology used to grow fava beans. “Fava beans are nitrogen-fixers. This means they excel at taking nitrogen from the air and transferring it into the soil, reducing the need for nitrogen fertilizers. And thereby improving soil fertility and water-holding capacities, and loosening the soil. All of which are vital for a rich harvest.”

In early May, Meelunie will bring the first commercial products from Denmark onto the market. “These are unique ingredients,” concludes Gijs, “that through their taste and application properties can help food manufacturers resolve formulation challenges. Ingredients that will make plant-based products genuinely tasty and functional, thereby helping accelerate the protein transition.”

Ingredients’ benefits:

- Pure food ingredients, each with unique functional properties

- Neutral colour and taste

- Competitively priced

- Suitable for wide range of food applications

- Short, sustainable supply chain

Innovations are crucial for the protein transition. New products, brands, marketing strategies, technologies, and crops contribute to the shift towards more plant-based food. However, reaching and retaining consumers remains a challenge. New ideas that yield long-term results are necessary. What innovations can further support the protein transition, and where can you make an impact? Get informed and inspired during the third edition of the Protein Transition Congress by Food&Agribusiness, March 14. Gijs van Elst will represent Meelunie during the breakout sessions with his presentation on Fava Beans: “Protein crop of the future?”